| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Star Power

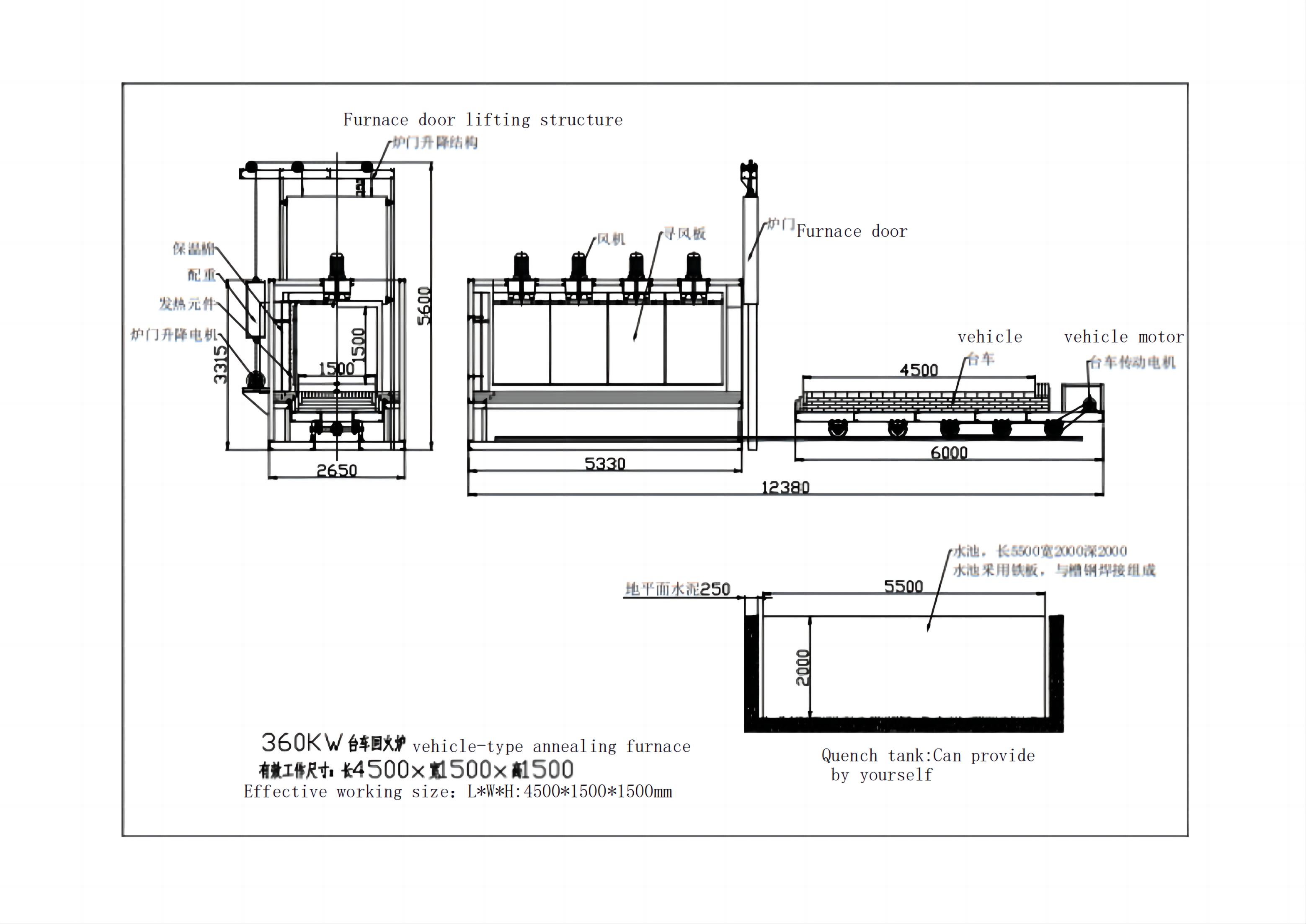

Model Number : 360KW

Certification : CU,ISO

Place of Origin : Guangdong, China

MOQ : 1 set

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 100 Set/Sets per Month

Delivery Time : 1 month

Packaging Details : metal frame with film

System : PLC

Voltage : 380V/220V Optional

Dimension(L*W*H) : 6505*4005*2000mm

Weight (T) : 8.1T

Power (kw) : 350 kw

Allocation list of the furnace body part

| order number | Package number / item number description | Specifications and models | quantity | Manufacturer name |

| 1 | furnace body | 1 | ||

| 2 | trolley | 1 | ||

| 3 | Aluminum silicate fiber cotton | STD | 1 | Shanxi Baojie fire-resistant thermal insulation material |

| 4 | heating element | 0Cr25Al5 resistance band, internal ceramic string sleeve fixed | 1 | Shanghai tree green |

| 5 | Furnace fan | 3.0KW | 4 | |

| 6 | Truck with force cycloidal motor | 5.5KW | 1 | |

| 7 | Went line motor with power of furnace door | 3KW | 1 | |

| 8 | Electric cabinet control box | 1 | ||

| 9 | pond | 1 |

| order number | ts | name | quantity | place of production |

| 1 | SCR-160 | Tuning module | 4 block | |

| 2 | WRNK-130 Φ5mm | thermocouple | Four | Zhaoqing, Guangdong |

| 3 | AI518E3JO | Intelligent digital display power control temperature control table | One | Xiamen udian |

|

|

Heat Treatment External Processing Vacuum Brazing Furnace Technology And Equipment Images |